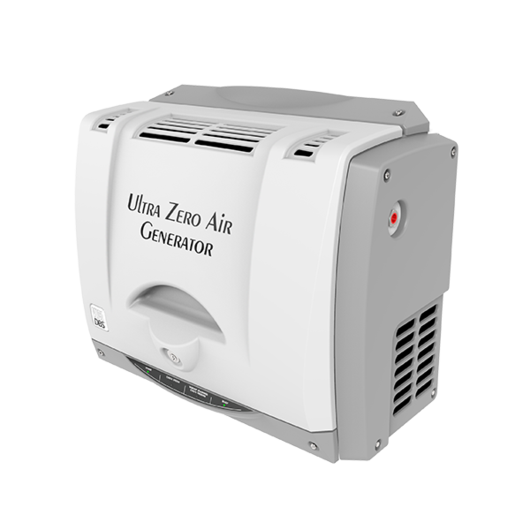

GT Plus 6000 Ultra-Zero Air Generator

- Home

- Generatoren

- Zero Air Generatoren

- GT Plus Ultra

The VICI DBS ® Ultra GT Zero Air Generator utilizes compressed air that is purified using a five step conditioning process. The resultant zero air is free from THC, CO, CO2, NOx, SOx, Ozone and water vapor, making it ideal all analyzer, TOC and specialist detector applications.

There are no moving parts making the generator extremely reliable and ideal to be installed directly in the laboratory or online. With flow rates up to 30 L/min one system can support multiple analyzers. With short pay back times, minimal maintenance and operator attention they are an ideal addition to provide gas to your analyzer.

FEATURES

▪︎ Produces a continuous supply of zero grade air

▪︎ On-demand supply 24/7

▪︎ Flow rate: 1 to 30 L/min

▪︎ Purity: Free from THC, CO CO2, O3, NOx & SOx

▪︎ Pressure: 4.5 to 10 barg (65 to 145 psig)

▪︎ Proprietary platinum catalyst technology

▪︎ Easy to install, operate and maintain

Benefits

▪︎ Eliminates dangerous high pressure cylinders helping to keep your employees safer

▪︎ Removes the logistics, inconvenience, downtime and costs of a cylinder system

▪︎ Flow capacity to match your specific instrument demands

▪︎ Meets and exceeds the requirements for the most demanding analyzers

▪︎ Low pressure relative to cylinders

▪︎ Superior air purification with long life catalyst technology

▪︎ Peace of mind

▪︎ Improve your laboratory work flow and productivity

Applications

ANALYZER APPLICATIONS

▪︎ CEM continuous emissions monitoring

▪︎ CO2 Analyzers

▪︎ Emissions Analyzers

▪︎ Online and Laboratory TOC

▪︎ Stack Gas Sampler

▪︎ Online and Laboratory FT-IR

Technical specifications

| Models & Specs | GT Plus 1500 | GT Plus 3000 | GT Plus 6000 | GT Plus 15000 | GT Plus 30000 |

|---|---|---|---|---|---|

| Flow mL/min | 1500 | 3000 | 6000 | 15000 | 30000 |

| Purity - hydrocarbons | <0.1 ppm | ||||

| Purity - CO | <0.1 ppm | ||||

| Purity - CO2 | <5 ppm | ||||

| Purity - NOx | <0.1 ppm | ||||

| Purity - SOx | <0.1 ppm | ||||

| Purity - O3 | <0.1 ppm | ||||

| Dewpoint | -50 ºC | ||||

| Inlet pressure barg (psig) | 4.5 to 10 (65 to 145) | ||||

| Outlet pressure barg (psig) | 1 (15) drop from inlet | ||||

| Inlet air quality | Clean dry compressed air ISO8573-1:2010 Class 1.2.1 | ||||

| Max HC in | 100 ppm | ||||

| Max CO in | 50 ppm | ||||

| Technology | Platinum catalyst | ||||

| LED indicators | Power on/off, system ready, errors | ||||

| Warm up time (minutes) | 45 | ||||

| Electrical supply | 110-120V 60Hz / 220-240V 50Hz | ||||

| Power consumption (watts) | 220 | 565 | 565 | 565 | 565 |

| Dimensions mm (inches) | 550W x 410H x 230D (21.6W x 16H x 9D) | 630W x 470H x 310D (24.8W x 18.5H x 12.2D) | |||

| Weight kg (lbs) | 10 (22) | 15 (33) | 15 (33) | 25.5 (56) | 25.5 (56) |

| Shipping dimensions mm (in) | 650W x 390H x 560D (25.6W x 15.3H x 22D) | ||||

| Shipping weight kg (lbs) | 14 (31) | 19 (42) | 19 (42) | 30 (66) | 30 (66) |

| Operating temp °C (°F) | 15 to 35 (59 to 95) | ||||

| Inlet connection | 1/4” Compression | ||||

| Outlet connection | 1/8" Compression | ||||

| Certification | CE, FCC, MET (UL and CSA compliant) | ||||